Drug development is expensive and often slow. The oft-cited Tufts estimates that the average cost of developing and winning marketing approval for a new drug is approximately $2.6 billion, with timelines running a decade or more. As with most things in drug development, those figures include both the cost of failed programs and the capitalised value of time.

What goes by the name of a “drug” is also changing. Small molecules will always be important, but biologics, gene therapies, and cell therapies are moving to centre stage. These modalities hold scientific promise but also introduce new technical, manufacturing, and regulatory complexities. It is also why biotech facilities EPC partners like Pharma Access provide industrial scale facilities that can materially shorten timelines, reduce surprises, and help sponsors move from concept to clinic with fewer missteps.

Biotech Facilities: What EPC and Consulting Involve

Good biotech EPC and facility and consulting is the highly practical intersection of scientific judgment, regulatory know-how, and project management where consultants and teams make the right decisions at the right time. Below are the main value propositions consultants bring to each stage of the drug lifecycle:

- Biomarkers, Diagnostics, And Study Design

Modern precision medicine programs depend on biomarkers and companion diagnostics. Consultants can advise on biomarker validation, companion diagnostic strategy, and how to design studies that produce regulatory-grade evidence for both drug and diagnostic.

Manufacturing and CQV (Commissioning, Qualification & Validation):

Biologics, cell and gene therapies, modular construction, and complex combination products need expertise, experience, and scale in manufacturing that often far exceed the capacity of early-stage teams which is where biotech can step in. Consultants provide CQV planning, process scale-up advice, and hands-on protocols that are easy to follow and reduce change orders during validation. Pharma Access, especially, helps with biotech success by delivering regulatory-ready cleanroom facilities that support complex biologics and advanced therapies..

How Pharma Access Drives Industry Excellence?

Pharma Access’s approach matches engineering, regulatory, and program execution so that clients convert winning strategies into validated, runnable operations and upskill their teams.

- End-to-end project delivery: From feasibility and process definition through to commissioning, qualification and validation (CQV), Pharma Access has regulatory rigour for managing capital projects.

- Modular facility solutions: Modular Mobile Facility (MMF) and other concepts that shorten construction timelines support phased scale-up. This is useful for programs that need early clinical supply before full-scale commissioning.

- CQV and QbD know-how: With over 24 years of experience and successful completion of 100+ projects across 18+ countries, Pharma Access brings proven methodologies to every engagement. The company’s approach centres on Quality by Design (QbD) principles and simulation-based engineering that reduces risks and accelerates project timelines.

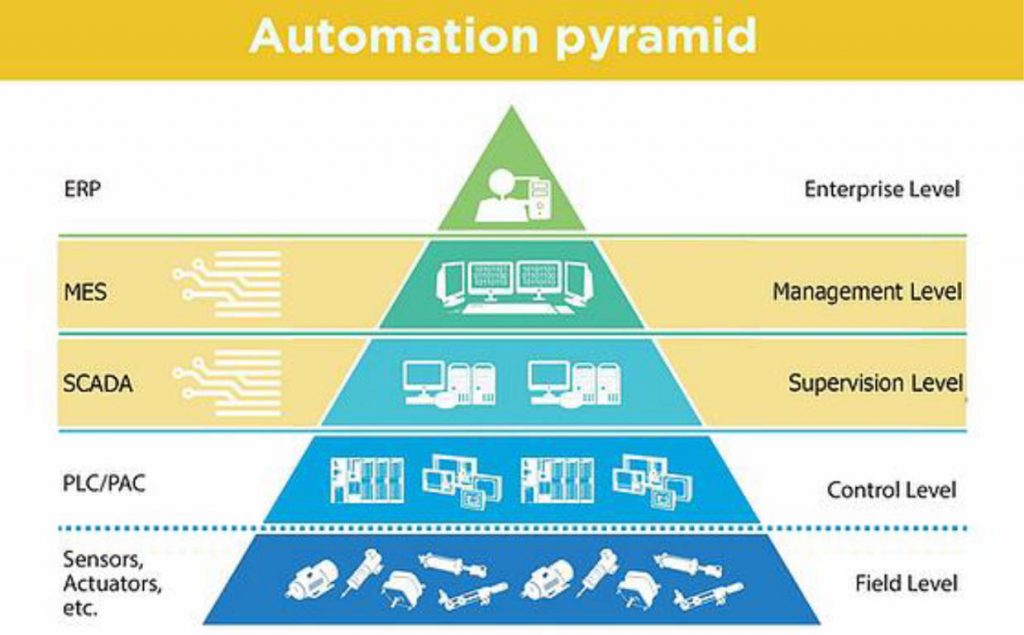

- Data-ready infrastructure: Our facilities are instrumented for analytics, digital twins, and future AI deployment, so your plant is a platform, not a project that supports biotech production.

- Regulatory engagement & submission support: Pharma Access helps coordinate regulatory interactions from IND/CTA planning through dossier readiness.

- Training and handover: Technology only succeeds when people are ready for it. Pharma Access supports training and competency programs to ease the transition to new processes and tools.

In short, Pharma Access combines engineering, regulatory and digital capabilities to let clients rapidly deploy modern development practices without sacrificing compliance or auditable traceability.

Reducing Time-to-Market Through Expert Guidance

Time is revenue and often patient impact, so shaving months or even weeks off development is meaningful. Consultants most frequently accelerate programs through three high-impact pathways:

- Smarter Facility Timelines:

Modular, prefabricated, and simulation-based design accelerate readiness, which is where Pharma Access shines. BIM, CQV & Quality by Design (QbD) by Pharma Access help make more efficient products that get quicker ISO certifications and are fully safety compliant.

- Early Risk Mitigation

Insights and experience from development teams mean they can often spot regulatory, CMC, or supply-chain risks early on and build those mitigations into the initial design. Pharma Access supplements these by noticing regulatory gaps in GMP design, utilities failures, and HVAC non-compliance.

The value of this work is obvious: preventing advanced manufacturing failures or regulatory deficiencies results in avoiding long-term delays that can last months or years while saving millions of dollars and potentially lives.

- Manufacturing Scale-Up Guidance:

Manufacturing is where many late-stage programs stumble, and scale-up is where companies with limited manufacturing knowledge fall flat on their face. This is also one of the places where Pharma Access has built their capabilities. Our EMP consultants guide process transfer, equipment selection, and qualifications so you don’t end up doing the rework that kills your launch dates. Companies that engage our manufacturing process equipment and machinery experts early in development avoid many common scale-up challenges that can delay product launches by months or years, especially by noticing early defects and ensuring regulatory compliance alongside high standard products.

Navigating Global Regulatory Complexities with Pharma Access:

Regulatory pathways have gotten more flexible, but remain exacting for safety reasons. The average USFDA review time decreased from 26.6 months before the Prescription Drug User Fee Act (1992) to 9.9 months after implementation, demonstrating how regulatory processes have become more efficient. As an example, the U.S. FDA’s Centre for Drug Evaluation and Research approved 55 novel drugs in 2023, an example of both robust innovation and active regulatory throughput, but each approval reflects a differentiated submission strategy and a lot of planning.

Regulatory agencies are also defining new frameworks for advanced modalities. The USFDA, for example, has its own lists of approved cellular and gene therapy products, and the agency’s guidance and review programs (including expedited pathways) are central to winning a regulatory plan. Biotech consulting services, such as those offered by Pharma Access, keep teams current on these programs and help design dossiers that anticipate regulator questions and challenges. We also ensure that our facilities meet USFDA, EMA, WHO, and GMP guidelines. Why is this valuable? It reduces inspection risks and cuts time that would have been wasted redoing compliance and safety.

Global launches are complex. EMA, FDA, PMDA, and other regulators have overlapping but distinct expectations. Biotech consulting, especially with Pharma Access, can coordinate parallel filings and regional strategies so you do not finish first in the U.S. only to lose months in translation elsewhere.

Helping Advanced Therapies and Biologics

The rise of advanced therapies has been striking. Regulatory approvals for cell and gene therapies, and the growing set of complex biologics, require manufacturing setups, clinical paradigms, and regulatory approaches that differ significantly from small molecules.

- Gene and Cell Therapy Development

These products require specialised manufacturing facilities, cryopreservation logistics and areas, and patient-specific workflows alongside controlled environments and modular units. EPA experts such as Pharma Access help design manufacturing networks and clinical supply chains that are practical, auditable, and acceptable to regulators such as the USFDA.

- Biologics Manufacturing and Development

From cell line selection, through comparability studies and immunogenicity assessment, biologic programs rely heavily on process knowledge. Consultants, such as the experts at Pharma Access, also support modular and clean rooms, CQV practices to make scale-up more likely to succeed and HVAC, Mechanical, Electrical & Piping setups to ensure compliance and operational efficiency, with Pharma Access having expertise in noting HVAC non-compliance, CQW, and Mechanical and Electric Pipping System setups.

Success Stories and Impact

Here are verified, public examples showing how combining modern manufacturing, digital tools, and strong program plans produces outcomes that regulators accept and supply chains can deliver.

- Continuous Manufacturing & Time/Cost Gains:

Work on continuous manufacturing has been a bellwether for industry change, and reports say that continuous approaches can significantly reduce manufacturing time and cut waste/costs in specific contexts. The USFDA and ICH have issued guidance supporting the adoption of continuous processes where the control strategy and validation are robust. Pharma Access has the digital and AI-ready facilities that enable such continuous operations.

- Digital Twins and Plant Digitisation:

Major companies have adopted digital twins and robust digital operations to improve decision speed and reduce downtime, and Pharma Access specialises in building such digital-ready infrastructure. Many partners have published projects on digital twin deployments for vaccine and biologics production, showing examples of how simulation and real-time data feed faster operational decisions.

- AI in Pharma R&D and Market Growth:

The AI in pharma market is rapidly expanding: multiple forecasts place the 2024–2034 market CAGR in the high-20s to low-30% range, with market sizes moving from under $2B in 2024 toward double-digit billions by 2032–2034. This is evidence of broad adoption across discovery, development and manufacturing analytics, making Pharma Access’ AI-ready facilities a way to future proof your biotech endeavors.

- Predictive Maintenance & Uptime:

Predictive maintenance is a repeatable value source in manufacturing operations. McKinsey and other industry analyses put predictive maintenance programs at roughly 30-50% reductions in equipment downtime when fully implemented. That’s direct, front-line impact on steadier production and fewer disrupted batches and this is where Pharma Access excels with our EPC programs and cutting-edge automation integration.

Our cases show that the combination of technical know-how, digital tools, and regulatory planning is not theoretical: it is how leading products moved through development and into supply efficiently.

Conclusion:

Drug development will always be resource-heavy, but the right expertise shortens missteps and turns complexity into manageable workflows, especially saving times and thus lives. Verified trends show regulators are approving novel therapies steadily, and that digital and continuous manufacturing approaches deliver measurable operational benefits. Alongside this, results show that AI/digital tools improve both discovery and plant performance when paired with good data and governance.

Biotech consulting is no longer optional and Pharma Access provides the EPC expertise needed to design trials that regulators accept, to build manufacturing that scales and to launch products that payers will reimburse. Aka Pharma Access translates scientific expertise into GMP-compliant audit-ready facilities that shorten manufacturing time and accelerate time-to-market and cost effectiveness.

If you want to accelerate biotech development while staying audit-clean and inspection-ready, alongside saving cost and lives, expert consulting paired with a delivery partner like PharmaAccess is a practical, proven route.

Frequently Asked Questions

Q: When is the best time for a biotech to get EPC partners?

Early is often the best. Engaging EPA partners before IND/CTA submissions and especially before critical scale-up milestones gives them the leverage to influence design, reduce risk, and prevent late rework.

Q: How does Pharma Access connect with client teams and consultants?

Good consulting augments, transfers, and accelerates organisational learning to make internal teams more effective, not redundant and that is what Pharma Access aims to do with their facilities.

Q: What makes Pharma Access different when working?

A combined focus on validated facility delivery, CQV, modular construction, and data-ready architectures to meet regulatory expectations while enabling modern manufacturing.

Q:How do Pharma Access’s modular and digital-ready facilities reduce biotech project risks?

By reducing human error and enhancing cybersecurity in automated projects as well as catching defects faster, Pharma Access’s facilities help reduce biotech risk.